Researchers from The Hebrew University of Jerusalem are taking the study of 3D printing and materials one step further in creating a new ink made from wood. In their recently published paper, ‘Additive Manufacturing of 3D Structures Composed of Wood Materials,’ authors Dr. Michael Layani, Prof. Shlomo Magdassi, Prof. Oded Shoseyov, and PhD student Doron Kam expound on the benefits of this new material, used in both binder jetting and extrusion 3D printing technology, with an international patent currently in the process of being filed for the new technique.

This new ink is made up of wood flour particles which spread out in a cellulose nanocrystal and hemicellulose matrix. The ‘flour,’ referred to by the team as WF, also offers a way to recycle further, using reclaimed wood, or materials that have been ground finely. Added to that is a binder of cellulose nanocrystals (CNCs) and xyloglucan (XG)—materials that have previously been used (separately of one another) in creating hydrogels.

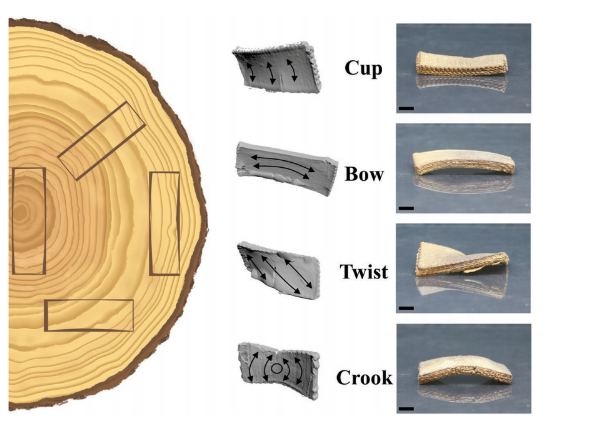

“The nanocomposite structure of wood consists of complementary materials and cellular structures, chemically bound to provide trees with the superior material properties, such as low density and the thermal resistance required to withstand extreme environmental conditions,” state the researchers. “At the plant cell wall dimension, cellulose crystallinity is the main strength-providing component in cellulose microfibrils and hemicelluloses, such as xyloglucan, glue the microfibrils together into a composite structure that is both strong and tough.”

3D printed wood is not exactly a new concept, with numerous techniques previously involving FDM 3D printing with plastic filaments. Other research teams have used materials such as wood chips blended with other powders like cement, silicone, and more (and often bound with toxic chemicals such as formaldehyde too, causing restrictions in use). In this new process, the authors explain that they used water-based inks—first optimizing the materials, and then optimizing ‘compositions in 3D printing.’

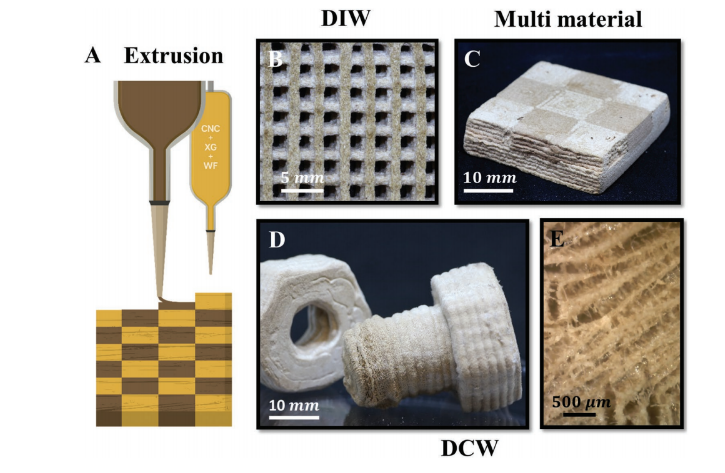

In extrusion, the researchers used both direct-ink writing and direct cryo-writing—with the process relying on the quality of the ink; ultimately, however, only some of the inks were suitable for use. Both techniques also required post-processing to dry the samples, resulting in volumetric decrease and ‘concurrent density increase’ in the DIW samples. The team noted that the end product, in either case, was so dense, it could be processed with tools that would normally be used on natural wood.

In using the direct cryo writing procedure, materials ranged in density—again, matching natural wood like balsa or even ebony. The team was able to create parts like a model chessboard, using both maple and eucalyptus-based inks.

“We noted that the object appeared homogenous, with no delamination between different parts, since the same binder composition was used for both inks,” stated the researchers.

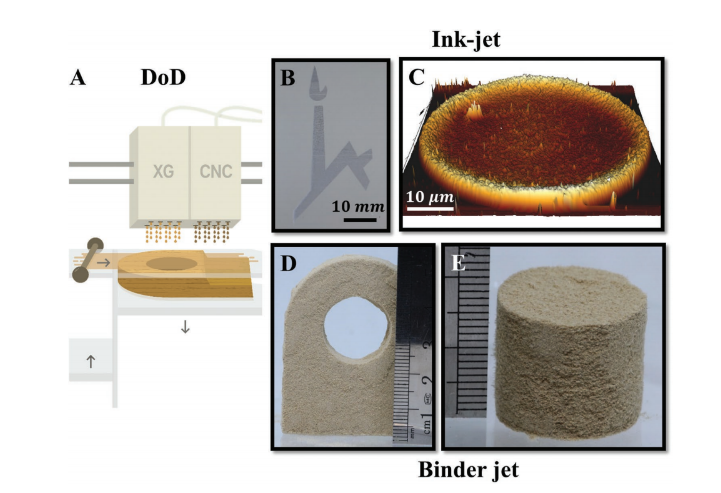

In binder-jet printing, the research team 3D printed on a solid substrate, with CNC inklet droplets demonstrating a ‘uniform and repetitive’ pattern. They also experimented with a multi-color 3D printer, using WF with an XG/CNC binder.

“This setup enabled control of the ratio between the two binder components as well as the ratio of binder to WF powder by control of the number of printed droplets,” stated the research team.

“After printing, we quantified the physical properties of objects printed with ink containing varying rations of XG and CNC. Mold casting was achieved by either casting in a mold followed by drying at RT or freeze casting followed by lyophilization. Different ratios of XG:CNC in aqueous suspension were mixed with WF from Eucalyptus at a constant total solid mass. It was found that the compressive modulus and strength increased with increasing CNC concentrations, for samples obtained by drying at RT.”

In performing ‘unconfined’ compression tests, the researchers also found that both modulus and strength were increasing along with increases in the binder, like natural wood. Thermal conductivity of the 3D printed wood samples was low; in fact, the researchers stated that it was remarkably so. They also noted some disintegration upon immersion in water, but the samples reverted to their initial form upon drying.

“The presented approaches for 3D printing of wood-based objects, enabled hierarchical structuring, and control over the macroproperties of the resulting objects. The ink components both bear a low environmental footprint and avoided usage of fossil oil-based resins that are commonly used in industrial engineered wood. We expect that the presented printing approaches and material compositions will open new directions in the field of additive manufacturing, overcome traditional wood industry barriers, and exploit woodwaste,” concluded the researchers.

3D printing draws many users who are extremely environmentally conscious, along with being concerned effects of plastics on the planet—and in regards to humans also, in biomedical applications; however, there are other worries too regarding toxicity and emissions. Researchers are achieving further success also with a variety of different materials that may prove to be better in the long run, along with enhancing products by using a growing variety of composites—including those with wood.