As the world inches closer to 2050, the importance of implementing and replacing emission-tied energy sources grows ever more urgent. Renewable energy technologies have thus become highly sought in the effort to reduce the world’s reliance on fossil fuels and eliminate the associated greenhouse gases generated from the industry.

One of the more popular and promising renewable technologies to emerge has been photovoltaics (PV), the conversion of sunlight into electricity. Its declining costs and rising efficiencies propelled solar energy production to impressive levels as PV capacity reached approximately 400 gigawatts (GW) worldwide by the end of 2017. According to the International Energy Agency (IRENA), Israel’s renewable energy production capacity reached 2300 megawatts (MW) by 2019, and over 95 percent of it came from solar energy. Let’s put these capacities into perspective: 1000 watts equals 1kW, 1 million watts equals 1MW, and 1 billion watts equals 1GW.

The power outputs of conventional solar panels today typically range from 225 to 365 watts. The higher the wattage, the more electricity one can generate throughout the day during sunlight hours. So, if a 300-watt solar panel, for instance, is being used in Israel, a country that receives an average of nine hours of sunlight per day, it would be able to produce 2,700Wh (watt hours), or 2.7 kilowatt hours (kWh) of renewable electricity (300 x 9).

But solar power can also produce considerable waste. Worldwide deployment of perovskite solar panels “poses environmental and economic problems due to degradation over time,” Israeli researchers suggested in a recent study of solar cell structure. And they developed a unique process to remove and replace degraded material, paving a path “for more sustainable green energy production in the future.”

Generating electricity and waste?

Despite solar power’s capability of heavily decarbonizing the energy sector and the likelihood of solar PV capacity to triple from its 2017 levels by 2023, harsh environmental and economic problems are slated to follow as a result of improper hazardous waste management. A solar panel’s operational lifespan usually ranges between 20 and 30 years mainly due to a combination of light erosion over time, temperature-related degradation, and cracked solar cells. After such time, chemicals such as lead (Pb) and cadmium (Cd) easily toxify their surroundings and leech into the ground, and open drinking water to contamination.

Due to the projected increases in installations, issues will begin to accumulate as greater numbers of solar panels reach their end-of-life (EOL) stages because their appropriate disposal has not been of much concern over the past 25 years of development.

According to data from IRENA, global solar panel waste was estimated at 250,000 metric tons by the end of 2016.

More specifically, Japan’s solar panel waste, for example, is projected to skyrocket from 10,000 to 800,000 metric tons by 2040, and no plans have been announced detailing their safe disposal. The state of California has also presented zero proposals for proper disposal despite their renowned environmental awareness. Even China, which operates twice as many solar panels as the United States, has no regulated strategy for degraded solar panels. While these countries are focused on researching effective recycling options for solar modules, the disadvantages of the processes include solar cell damage, costly equipment, high energy demands, and hazardous emissions.

Perovskite potential

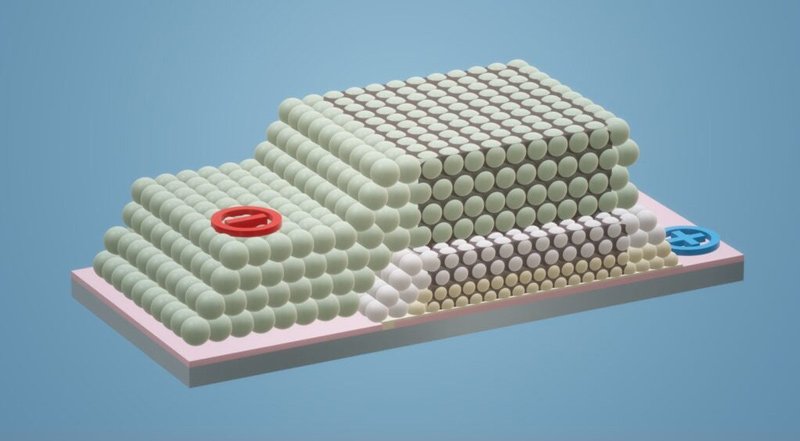

Extensive research to determine an alternative to traditional silicon-based solar cell material is being conducted, and thin-film perovskite solar cells are currently the top contender for photovoltaic advancement. Unlike traditional solar panel material, perovskites are an entirely different class of material defined by their unique crystallographic structure, which makes them just as effective at converting photons from sunlight into electricity. Beyond their comparable efficiency, there are other advantages associated with perovskite solar cells.

One advantage relates to cost. The material making up perovskite solar cells are entirely man-made, which can be produced at a low cost through a process called solution processing, the same method that is used to make newspapers. Because of this, perovskite manufacturing is feasibly scalable, meaning that the cost of production has the potential to be much lower relative to other solar panel technologies. By contrast, conventional solar PV cells are made using crystalline silicon, a material which must be mined from the earth and processed before being used to make high quality solar cells.

“If you look at the cost of existing PV technologies, even though they’ve dropped considerably, they are still expensive, complex semiconductor systems that are very difficult to manufacture,” says Joe Berry, Senior Scientist at the National Renewable Energy Laboratory of the US Department of Energy. Utilizing a perovskite solar cell will thus reduce complications and the cost associated with solar cell manufacturability.

Unfortunately, there is still one problem: degradation over time. Because the photoactive perovskite materials are usually situated between other layers of the solar panel, it prevents the solar cell from being recycled. Like traditional silicon-based solar panels, it would therefore create similar EOL waste generation issues and repeat a cycle of costly manufacturing circumstances.

New Israeli research suggests new path forward

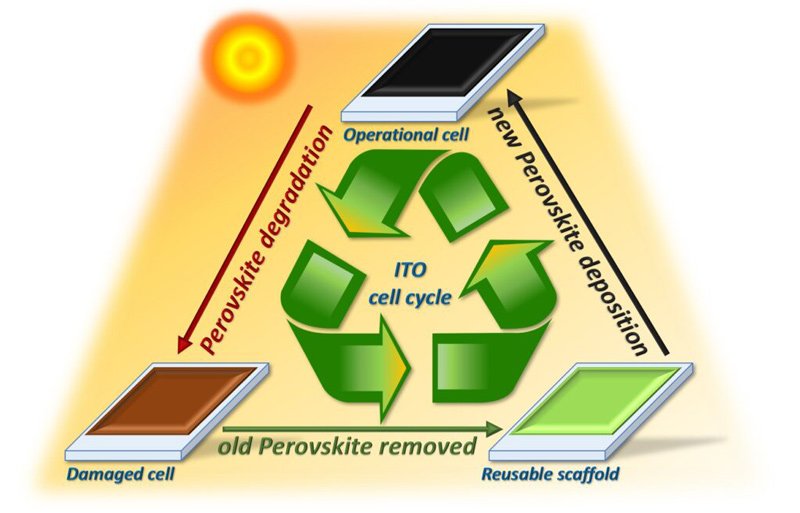

Thankfully, however, researchers from the Hebrew University have recently found a way to improve the lifespan and functionality of perovskite solar cells by designing the solar module in such a way that the degraded perovskite can be removed and replaced, thereby fully restoring its photovoltaic capabilities and avoiding problematic EOL waste build-up. Although, this was not the initial motivation of the research.

“This was not planned from the beginning,” says Professor Lioz Etgar, senior lecturer at Hebrew University’s Institute of Chemistry. “The motivation was to find a way to develop a low-cost solar cell that can be made quite easily, that could deliver high efficiency, and work for a longer period of time.”

In terms of efficiency, Etgar and his research team are making promising headway. “If you compare our solar cells to other perovskite cells – let’s say the best efficiency perovskite cells – our efficiency is a little bit lower than them today,” he explains. “However, we already made progress in the last year. Even after our study was published, we already have a more efficient panel than before, but it’s still a bit lower than the higher efficiency perovskite.”

It was not until later in the team’s research into solar cell structure that they found they could remove and replace the degraded semiconductor perovskite with fresh perovskite materials. “It’s very unique because there is no solar cell based on perovskite or even not based on perovskite that can do this today,” says Etgar.

While acknowledging the approximate 25-year expected lifespan of traditional solar cells today, Etgar and his research team still have some work ahead of them. “Right now, our solar cells can last several years before degrading and needing to be replaced. But this is still in development, which means that our solar cells still don’t quite have the desired durability that we want.”

Although degraded perovskite goes into special waste treatment after it is removed, Etgar emphasized the material’s recyclability. “Even if it degrades and you can wash it and use it another time. You wash and transition it into a container, then you stir and heat it a little bit, and then it can be used again.”

In addition to Etgar’s research team, cumulative efforts of European startups like Oxford PV and Saule Technologies have also been working to expedite the commercial arrival of perovskite-based solar cells. “It could take between 2-5 years,” he estimates.

Etgar speculates, however, their eventual integration within Israel will be initially geared towards independent off-grid applications rather than centralized solar energy farms.

“It will probably go to buildings, agriculture, and indoor application—even in your office and your phone. I see this will be the first application of those kinds of solar cells because today you have the competitive technology of silicon-based solar cells,” he concludes.